20t/h Steam Boiler Relocation

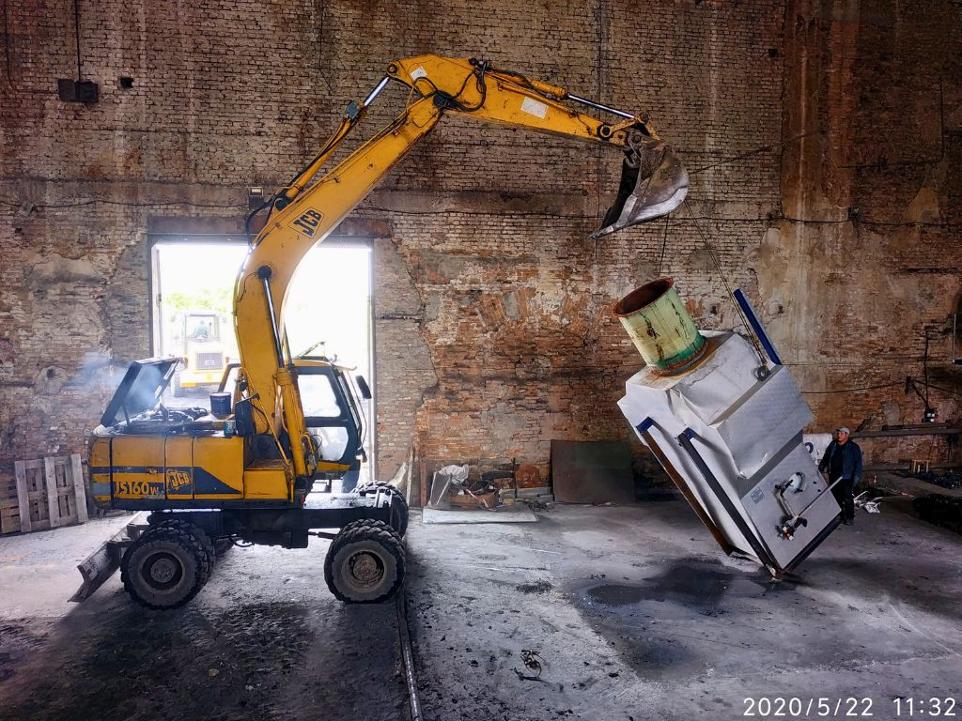

In 2020, our EnergoDesign team undertook a significant project - the relocation of a 20t/h steam boiler.

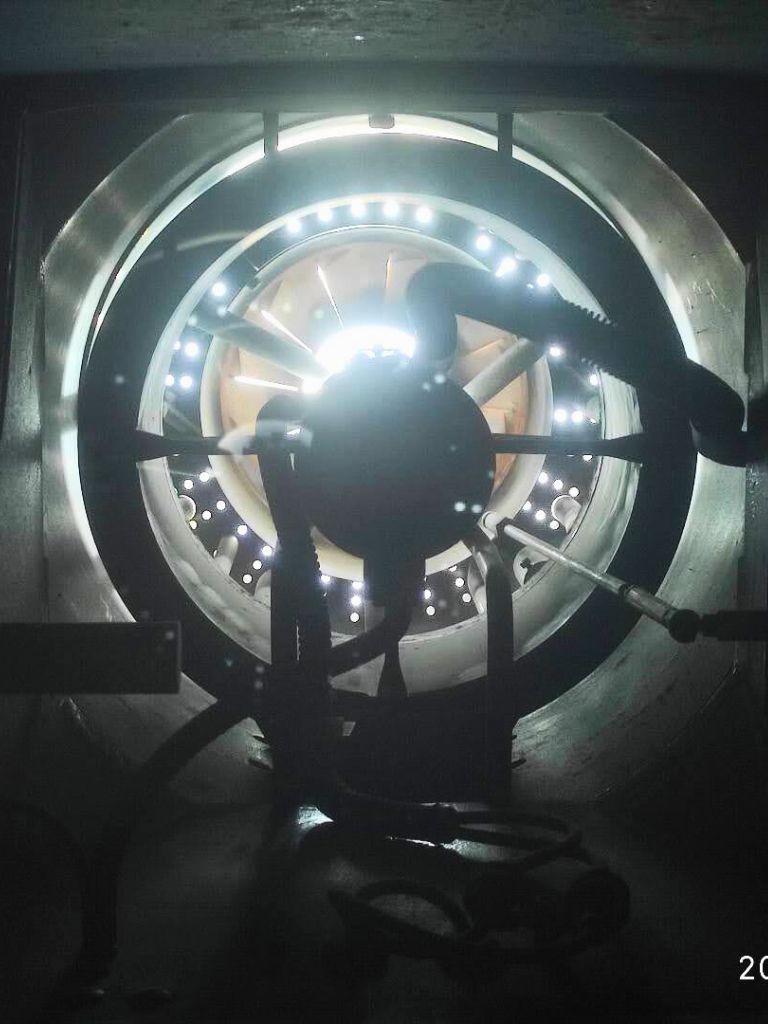

This project involved the purchase, dismantling, and revision of two fire-tube boilers, each with a capacity of 10 tons per hour, along with auxiliary equipment. The dismantling process took two weeks, during which our team meticulously checked all equipment components.

Simultaneously with the dismantling process, we developed a project for installing the equipment at a new location. Thanks to our efficient work and coordination, we were able to install the equipment and get it up and running in a month and a half.

It's worth noting that all work was carried out during a quarantine period due to the COVID-19 epidemic. Despite these challenges, our team successfully completed the project, adhering to all necessary safety measures.

This project is a testament to our ability to work effectively even under the most challenging conditions, providing high-quality service and reliable solutions.