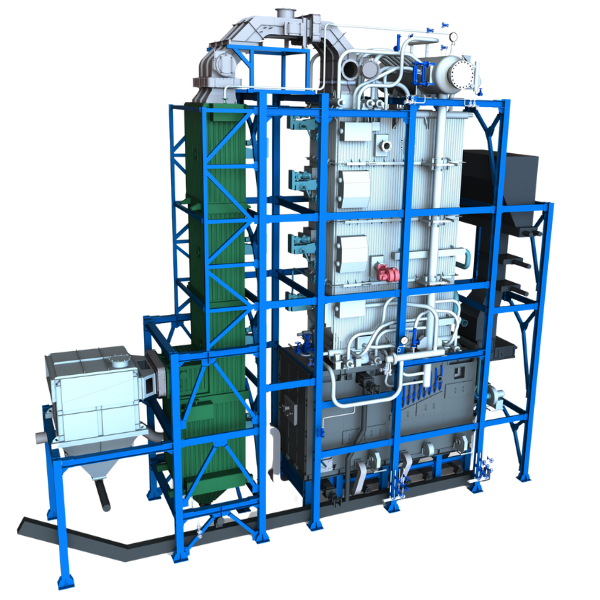

Industrial water-tube biomass steam boiler

Natural circulation. Gas-tight membrane-wall design.

We engineer and manufacture gas-tight, natural-circulation water-tube steam boilers for biomass and low-calorific fuels. A tall furnace and low furnace heat release provide sufficient residence time for complete burnout and stable operation. The boiler layout is engineered to the customer’s process requirements and actual fuel characteristics.

Learn When to Choose a Water-Tube Boiler

Technical range and limits:

- Boiler type: water-tube, natural circulation, gas-tight (membrane walls)

- Steam capacity: 1–18 t/h

- Steam pressure: up to 24 bar

- Steam: saturated or superheated; superheat up to 370°C

- Load range: 40–100%

- Fuel: biomass and low-calorific fuels up to 5,500 kcal/kg

- Compliance: PED/CE available (project-dependent)

Upper values reflect our proven range; higher parameters can be engineered on request.

Environmentally Friendly

Thanks to the use of biomass and low-grade fuels, our boiler is not only efficient but also environmentally friendly. This promotes green energy and allows the use of agricultural waste as fuel.

The design of our DBW steam boiler allows for the combustion of the following types of fuel, but we are not limited to these options. This list can be expanded, and it is far from exhaustive:

- sunflower husk

- poultry factory waste

- straw from oats and other cereals

- peat

- lignin

- corn stalk

- pellets

Галерея реалізованих проєктів

Фото з виробництва, монтажу та пусконалагодження парових котлів