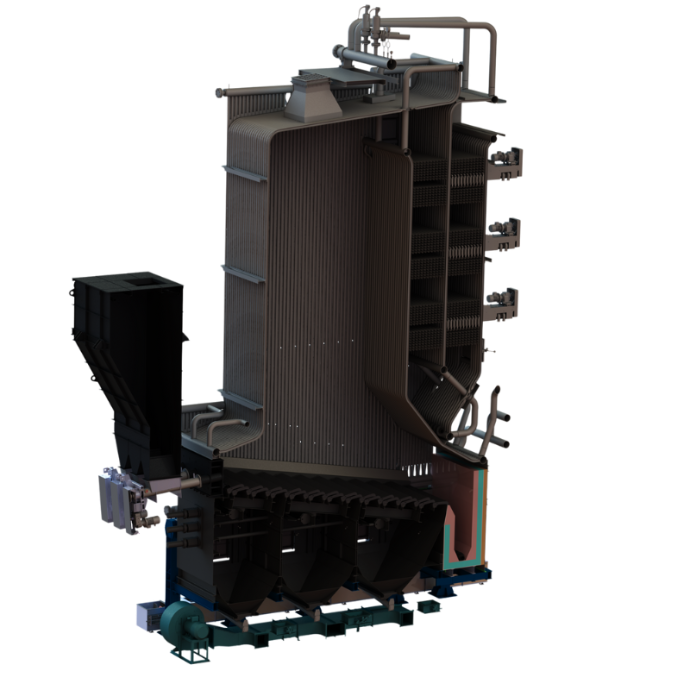

Water-Tube Hot Water Boilers

The BHW family is a configurable range of water-tube hot-water boilers. Each unit is engineered to customer-specific duty with thermal output up to 10 MW and water parameters up to 175 °C and 25 bar (2.5 MPa). The boilers feature a membrane-wall design with forced circulation, combining robust construction with advanced combustion and control technology. They are designed to burn mixed fuels – municipal waste, agricultural residues and a wide range of biomass – turning low-grade feedstocks into useful thermal energy for process and district heating.

Key Benefits

- Tailor-made power and pressure. Custom-designed units with thermal output up to 10 MW and water pressure up to 25 bar for demanding high-temperature loads.

- Flexible fuel handling. Reciprocating moving grate and zoned air supply for municipal waste, agro by-products, woody biomass and pellets.

- Durable water-tube construction. Gas-tight membrane walls and forced-circulation circuits distribute heat evenly and resist thermal stress.

- Efficient and compliant. Nominal efficiency of 83–85 % helps minimise fuel consumption; emission-control systems can be integrated to meet local regulations.

- Smart automation. PLC-based control of ignition, fuel and air, water temperature and draft, with SCADA integration and built-in safety interlocks.

- Low maintenance. Automatic ash removal and pneumatic cleaning of heating surfaces reduce manual work and downtime.

Project Reference Gallery

Photos from manufacturing, erection and commissioning of BHW hot-water boilers.