Innovative Boiler Reconstruction: Enhancing Efficiency with Moving Grate Combustion

In 2021, Energo Design successfully undertook a significant project involving the reconstruction of a boiler that had been installed by our team 20 years ago. Initially designed for buckwheat husk combustion using vertical vortex technology, the boiler needed an upgrade to accommodate the changing waste profile of the enterprise, including oat husk residues.

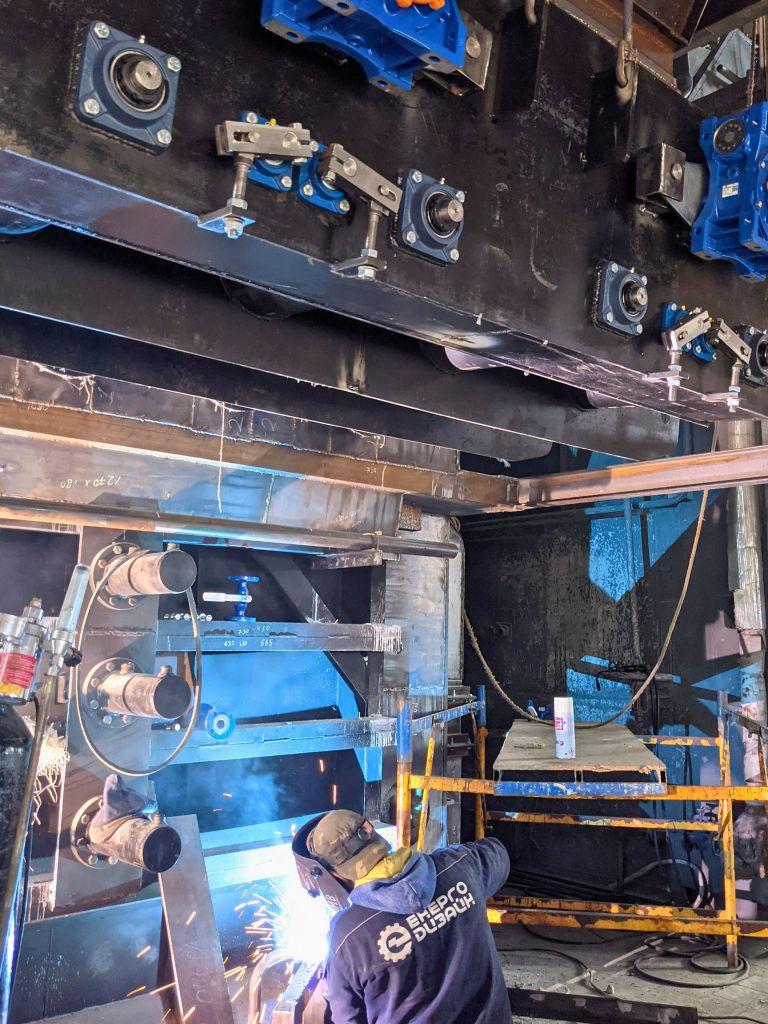

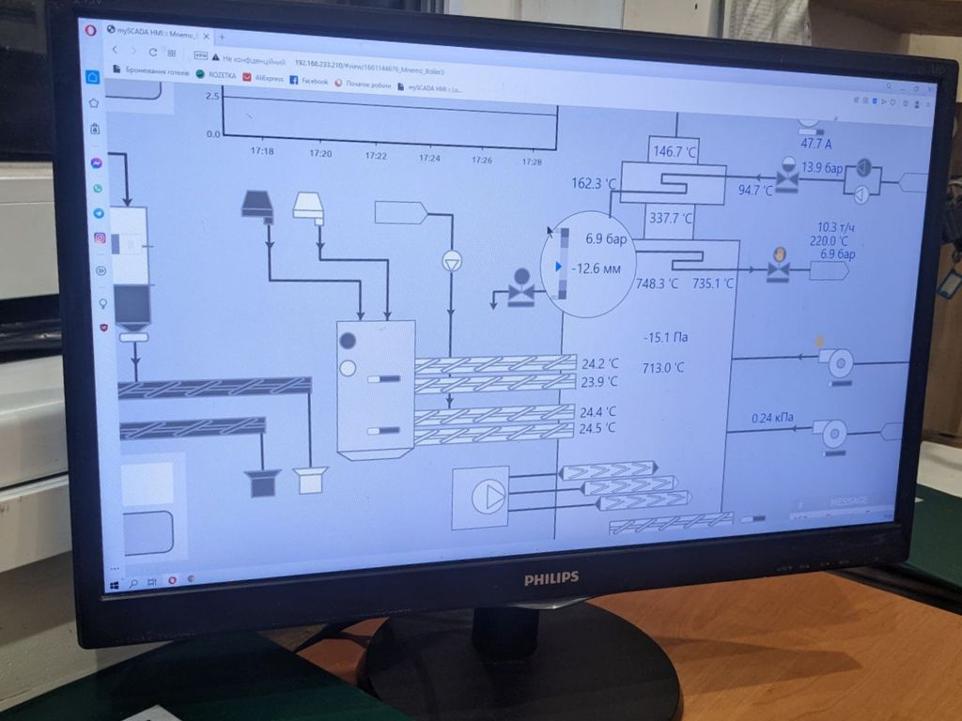

Our solution involved a transition to layer combustion on a moving grate. The project required comprehensive design documentation, including combustion process modelling, boiler reconstruction, and geometry alteration of the combustion chamber.

The successful implementation of this project enabled the enterprise to efficiently use elevator waste and oat husk residues as fuel, improving the boiler's efficiency and power when using these new fuel types. The boiler's productivity after reconstruction is 10 tons of steam per hour, with a pressure of 14 bars and a superheat temperature of 250°C.