Grain Dryer Conversion to Steam Heating

Completion Date: 2022

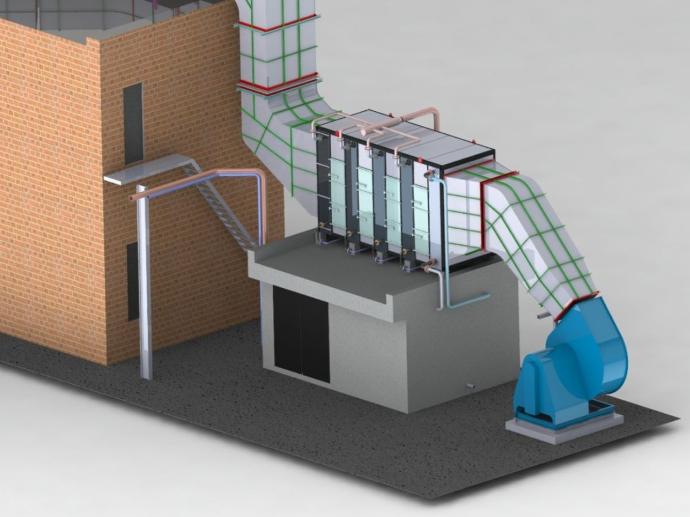

Project Description: This project involves the conversion of a grain dryer of type A1-DSP-50 to steam heating from a boiler that operates on biomass, specifically elevator waste.

We installed a steam calorifier that allowed us to prepare 120 thousand cubic meters of air with a temperature of 130°C, moving away from the use of natural gas. As part of the project, we developed project documentation, performed engineering calculations, and manufactured and installed equipment.

Results: Thanks to this project, the grain dryer operates in corn grain drying mode without the use of natural gas.